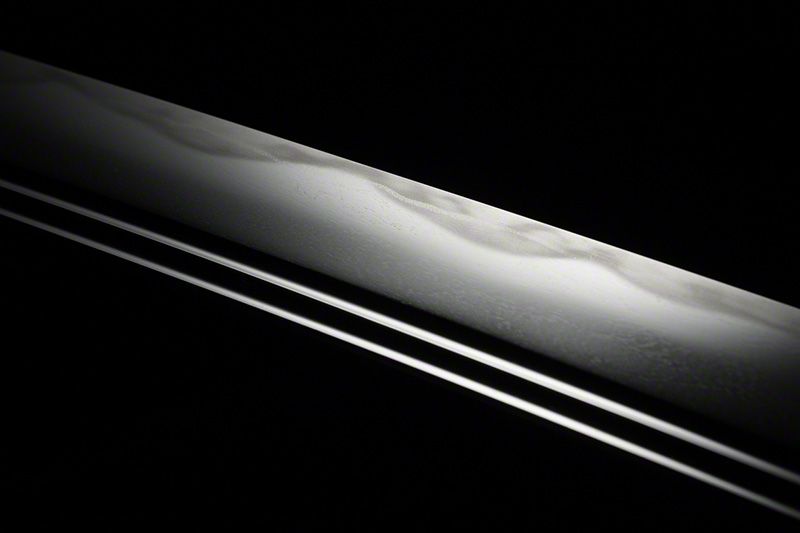

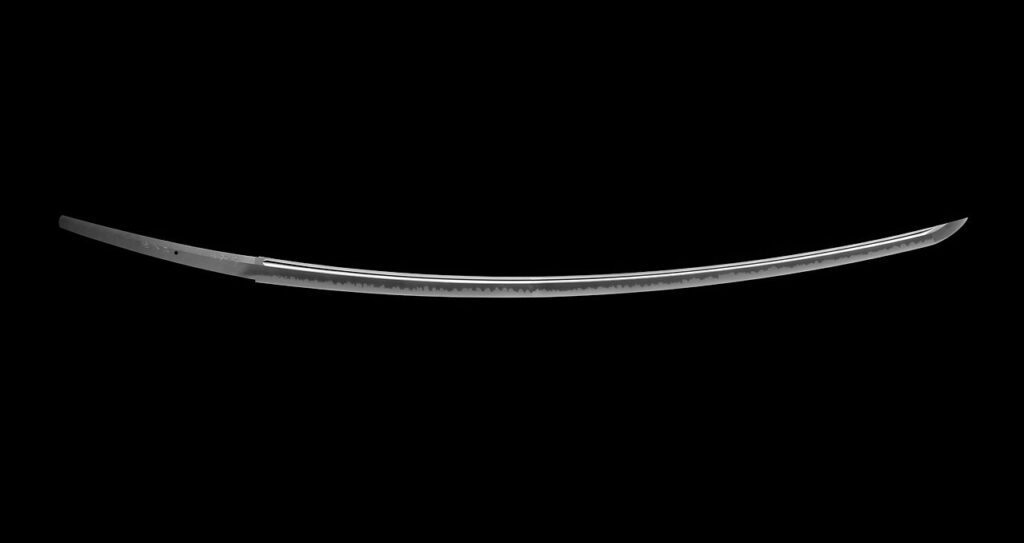

The naked austerity of the hard steel, the powerful sheen of the hamon patterning on the blade, the sleek beauty of the delicately curved blade—like porcelain, the Japanese katana is a work of art with a unique aesthetics of its own.

Miyairi Norihiro is a modern master of the Japanese sword, the inheritor of a proud tradition that flourished during the glory days of samurai culture from the twelfth to the fourteenth centuries. His swords have an almost supernatural power to inspire and enchant.

Besides his work as a swordsmith, Miyairi also makes the delicate tōsu knives that were cherished as elegant accessories and accouterments by the nobility as far back as the eighth century and survive today as part of the nation’s cultural heritage in the Shōsōin treasure house in Nara. Miyairi is a master of every stage of the production process, from making the blade to carving the exquisite bachiru patterns into dyed ivory and the intricate metal chasing and decoration.

Photographs by Kimura Naoto

Text by Kutsuwada Satsuki